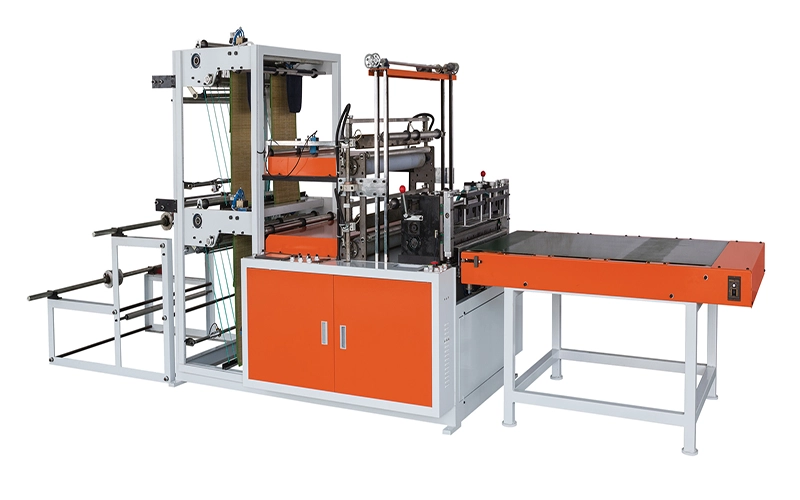

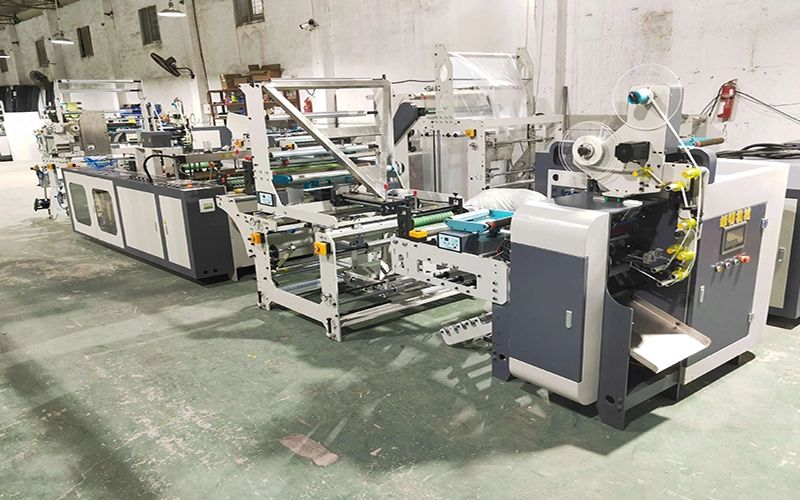

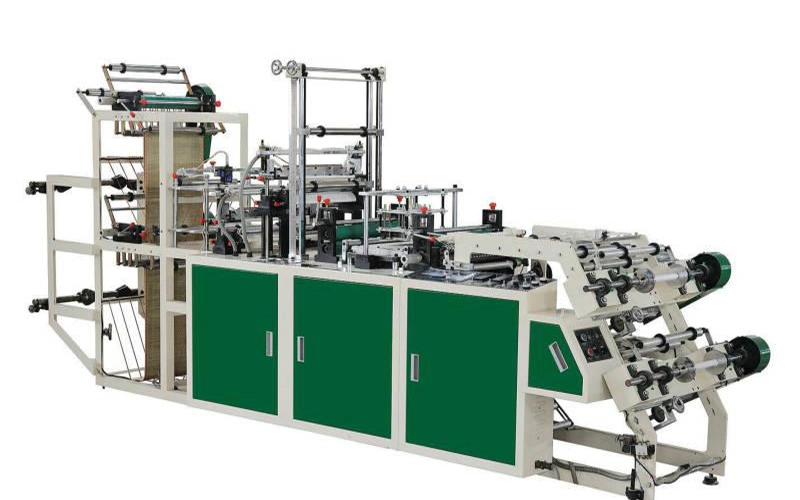

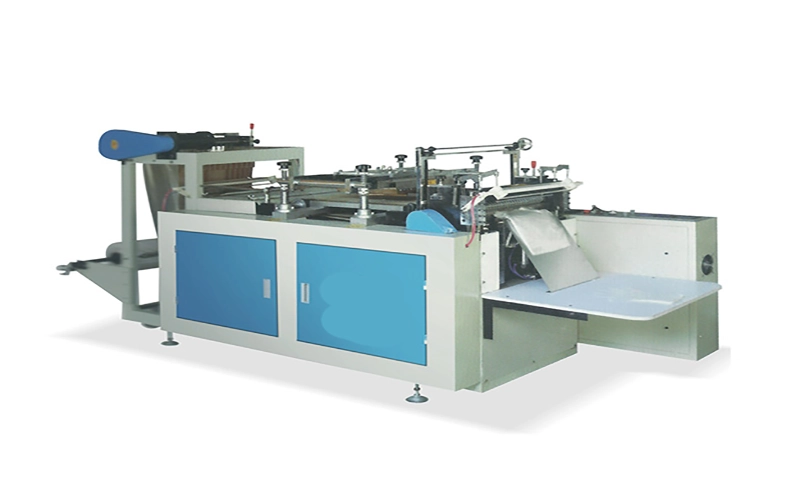

The high-speed plastic vest bag making machine integrates PLC control, servo motor precision, and LCD data display for efficient, automated production. It completes feeding, cutting, punching, and conveying in one cycle, with optional accessories like a hydraulic feeder and automatic folder for enhanced performance. Known for high efficiency, reliability, and industry impact, it sets a new standard in packaging technology, ideal for diverse sectors needing streamlined production solutions.